Maytag MGD7000XW Installation Manuel d'utilisation

Page 8

8

*5

3

/

4

"

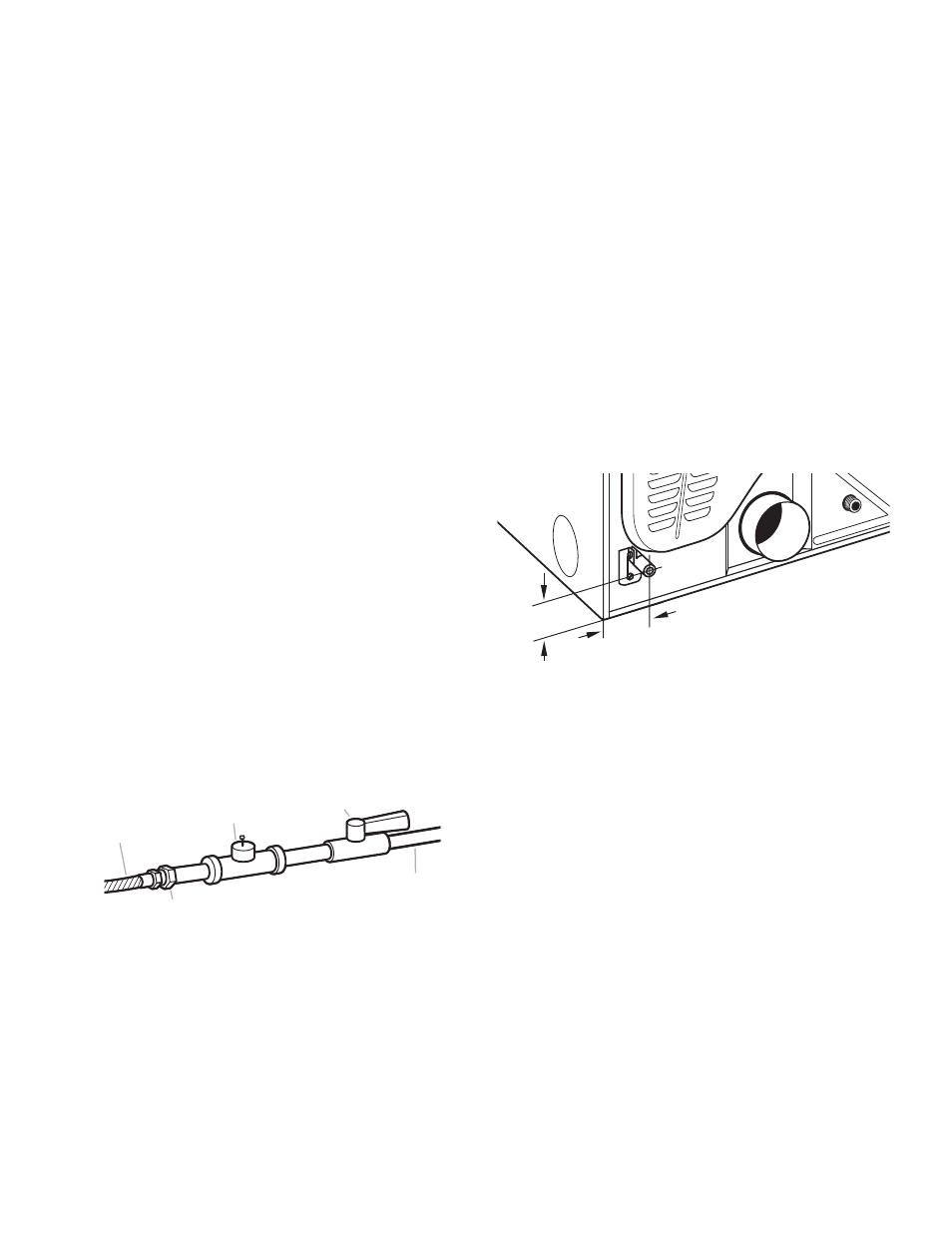

(146 mm)

1

1

/

2

"

(38 mm)

†®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

3/8" NPT dryer gas pipe

GAS SUPPLY LINE

Option 1 (Recommended Method)

Flexible stainless steel gas connector:

If local codes permit, use a new flexible stainless steel gas

■

connector (Design Certified by the American Gas Association

or CSA International) to connect your dryer to the rigid gas

supply line. Use an elbow and a 3/8" flare x 3/8" NPT adapter

fitting between the stainless steel gas connector and the dryer

gas pipe, as needed to prevent kinking.

Option 2 (Alternate Method)

Approved aluminum or copper tubing:

Must include 1/8" NPT minimum plugged tapping accessible

■

for test gauge connection, immediately upstream of the gas

connection to the dryer. See illustration.

1/2" IPS pipe is recommended.

■

3/8"approved aluminum or copper tubing is acceptable for

■

lengths under 20 ft. (6.1 m) if local codes and gas supplier

permit.

If you are using Natural gas, do not use copper tubing.

■

Lengths over 20 ft. (6.1 m) should use larger tubing and

■

a different size adapter fitting.

If your dryer has been converted to use LP gas, 3/8" LP

■

compatible copper tubing can be used. If the total length of the

supply line is more than 20 ft. (6.1 m), use larger pipe.

NOTE: Pipe-joint compounds that resist the action of LP gas

must be used. Do not use TEFLON

®†

tape.

Must include shut-off valve

■

In the U.S.A.:

An individual manual shut-off valve must be installed within

six (6) ft. (1.8 m) of the dryer in accordance with the National

Fuel Gas Code, ANSI Z223.1. The location should be easy to

reach for opening and closing.

In canada:

An individual manual shut-off valve must be installed in

accordance with the B149.1, Natural Gas and Propane

Installation Code. It is recommended that an individual

manual shutoff valve be installed within six (6) ft. (1.8 m) of

the dryer. The location should be easy to reach for opening

and closing.

GAS SUPPLY cONNEcTION REQUIREMENTS

Use an elbow and a 3/8" flare x 3/8" NPT adapter fitting

■

between the flexible gas connector and the dryer gas pipe,

as needed to avoid kinking.

Use only pipe-joint compound. Do not use TEFLON

■

®†

tape.

This dryer must be connected to the gas supply line with a

■

listed flexible gas connector that complies with the standard for

connectors for gas appliances, ANSI Z21.24 or CSA 6.10.

bURNER INPUT REQUIREMENTS

Elevations above 2,000 ft. (610 m):

When installed above 2,000 ft. (610 m) a 4% reduction of the

■

burner Btu rating shown on the model/serial number plate is

required for each 1,000 ft. (305 m) increase in elevation.

Gas supply pressure testing

The dryer must be disconnected from the gas supply piping

■

system during pressure testing at pressures greater than

1/2 psi.

DRYER GAS PIPE

The gas pipe that comes out through the rear of your dryer has

■

a 3/8" male pipe thread.

A. 3/8" flexible gas connector

B. 3/8" pipe to flare adapter fitting

C. 1/8" NPT minimum plugged tapping

D. 1/2" NPT gas supply line

E. Gas shutoff valve.

A

B

E

D

C

* NOTE: If the dryer is mounted on a pedestal, the gas

pipe height must be an additional 10” (254 mm) or

15.5” (394 mm) from the floor, depending on the pedestal

model. For a garage installation, the gas pipe height must

be an additional 18” (460 mm) from the floor.