Venting, Make gas connection, Venting requirements – Maytag MGDX6STBW Installation Manuel d'utilisation

Page 11: Plan pipe fitting connection, Connect gas supply to dryer, Open shut-off valve, Warning, Flexible metal vent

11

A

B

D

C

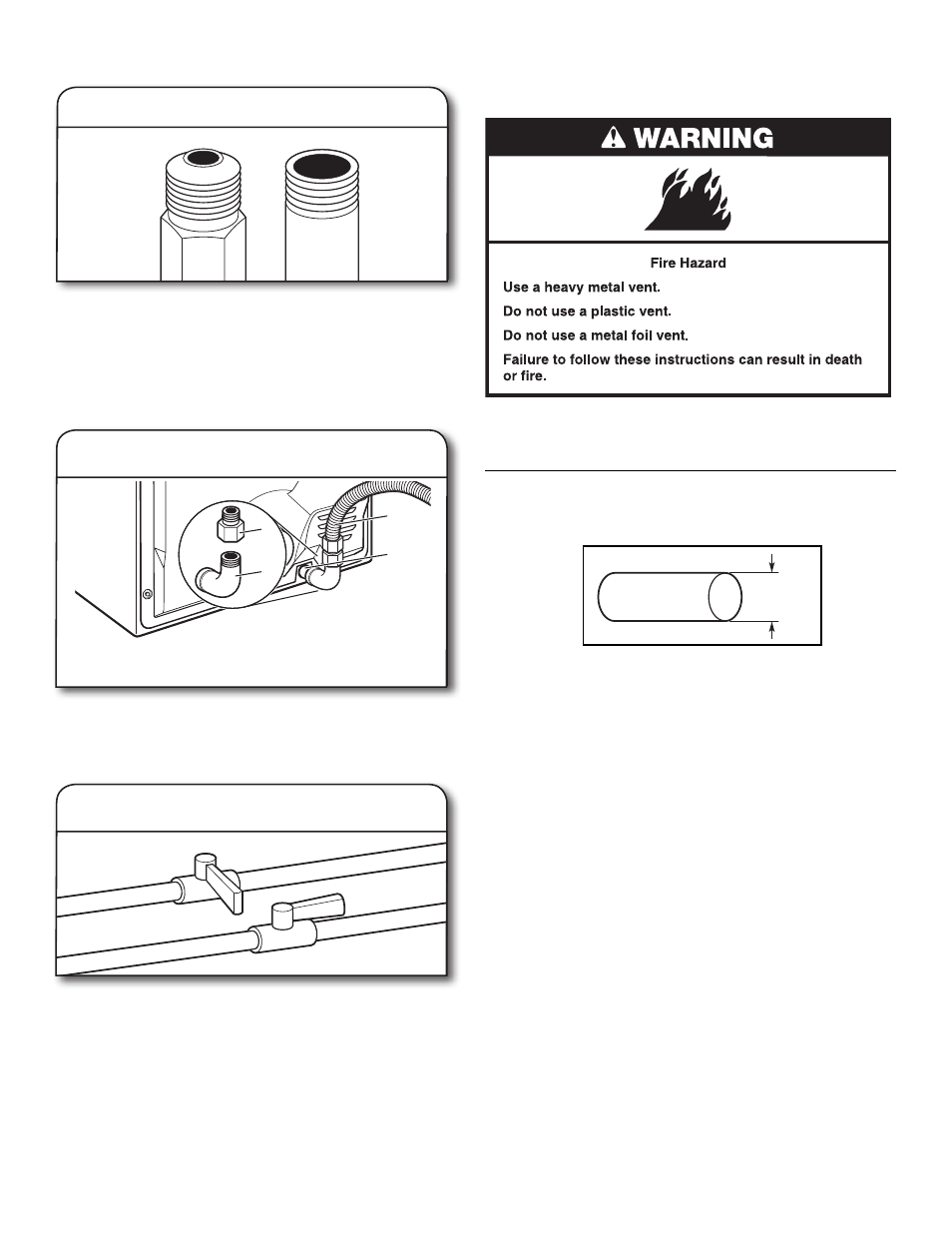

Plan pipe fitting connection

2.

A combination of pipe fittings must be used to connect dryer

to existing gas line. A recommended connection is shown.

Your connection may be different, according to supply line

type, size, and location.

A. 3/8" flexible gas connector

B. 3/8" dryer pipe

C. 3/8" to 3/8" pipe elbow

D. 3/8" pipe-to-flare adapter fitting

Open shut-off valve in supply line; valve is open when handle

is parallel to gas pipe. Then, test all connections by brushing

on an approved noncorrosive leak-detection solution.

Bubbles will show a leak. Correct any leaks found.

†®TEFLON is a registered trademark of E.I. Dupont De Nemours and Company.

A

B

Connect gas supply to dryer

1.

Remove red cap from gas pipe. Using a wrench to tighten,

connect gas supply to dryer. Use pipe-joint compound

on threads of all non-flared male fittings. If flexible metal

tubing is used, be sure there are no kinks.

NOTE: For LP gas connections, you must use pipe-joint

compound resistant to action of LP gas. Do not use

TEFLON

®†

tape.

Make Gas Connection

Closed valve

Open valve

Open shut-off valve

3.

Non-flared

male fitting

Flared

male fitting

Venting

Venting Requirements

4"

(102 mm)

4" (102 mm) heavy metal exhaust vent

WARNING:

To reduce the risk of fire, this dryer MUST BE

EXHAUSTED OUTDOORS.

IMPORTANT:

Observe all governing codes and ordinances.

Dryer exhaust must not be connected into any gas vent,

chimney, wall, ceiling, attic, crawlspace, or a concealed space

of a building. Only rigid or flexible metal vent shall be used for

exhausting.

■

Only a 4" (102 mm) heavy metal exhaust vent and clamps may

be used.

■

Do not use plastic or metal foil vent.

Rigid metal vent:

■

Recommended for best drying performance and to avoid

crushing and kinking.

Flexible metal vent:

(Acceptable only if accessible to

clean)

■

Must be fully extended and supported in final dryer location.

■

Remove excess to avoid sagging and kinking that may result

in reduced airflow and poor performance.

■

Do not install in enclosed walls, ceilings, or floors.

■

The total length should not exceed 7

3

/

4

ft. (2.4 m).

NOTE:

If using an existing vent system, clean lint from entire

length of the system and make sure exhaust hood is not plugged

with lint. Replace plastic or metal foil vents with rigid metal

or flexible metal vents. Review “Vent System Chart” and, if

necessary, modify existing vent system to achieve best drying

performance.