Caple CR9202 Manuel d'utilisation

Page 9

GAS ADJUSTMENT

Z

APPLIANCE MAINTENANCE

E 14

25 W - 230 V~

T300°C

A

REPLACEMENT OF THE CABLE

In case the cable is damaged, replace it in accordance with the

following instructions:

- open the box of the supply board as described on the picture

below;

- unscrew screw “A” fixing the cable;

- replace the cable with one of the same lenght and in accordance

with the features described on the table; switch the appliance

off, and close the gas tap

- the ‘green-yellow” earth wire must be connected to the terminal

“ “ and it must be about 10 mm longer thean the live wires;

- the “blue” neutral wire must be connected to the terminal marked

with letter “N”;

- the live wire must be connected to the terminal marked with letter

“L”.

Conversion to LPG

Always isolate the cooker from the electricity supply, turn off the

gas supply temporarily and proceed as follows.

- change the injectors,

- adjust the minimum flow of the burners.

REPLACEMENT OF WORK-TOP INJECTORS

In order to change the work-top injectors, it is necessary to act as

follows: remove the grids, remove burners and flame-spreaders

(see fig.A), change the injector (see fig.B) and replace it with

another one suitable for the new type of gas (see table D). Re-

assemble everything in the opposite direction, paying attention to

place the flame-spreader in the right way on the burner.

TAB. D

GENERAL INJECTORS TABLE

Kind of gas

mbar Nozzle

Burners

Power Watt

Consum.

mm/100

Posizione-type

max.

min.

max.

115

-Rapide

3000

750

286 l/h

NATURAL

20

97

-Semi rapide

1750

480

167 l/h

72

-Auxiliary

1000

330

95 l/h

128 -Triple crown

3300 1300 315 l/h

120

- Fish

2900

1500

277 l/h

G.P.L.

30

85

-Rapide

3000

750

219 g/h

BUTANE

28

65

-Semi rapide

1750

480

128 g/h

PROPANE

37

50

-Auxiliary

1000

330

73 g/h

93

-Triple crown

3300

1300

241 g/h

85

- Fish

2900

1500

211 g/h

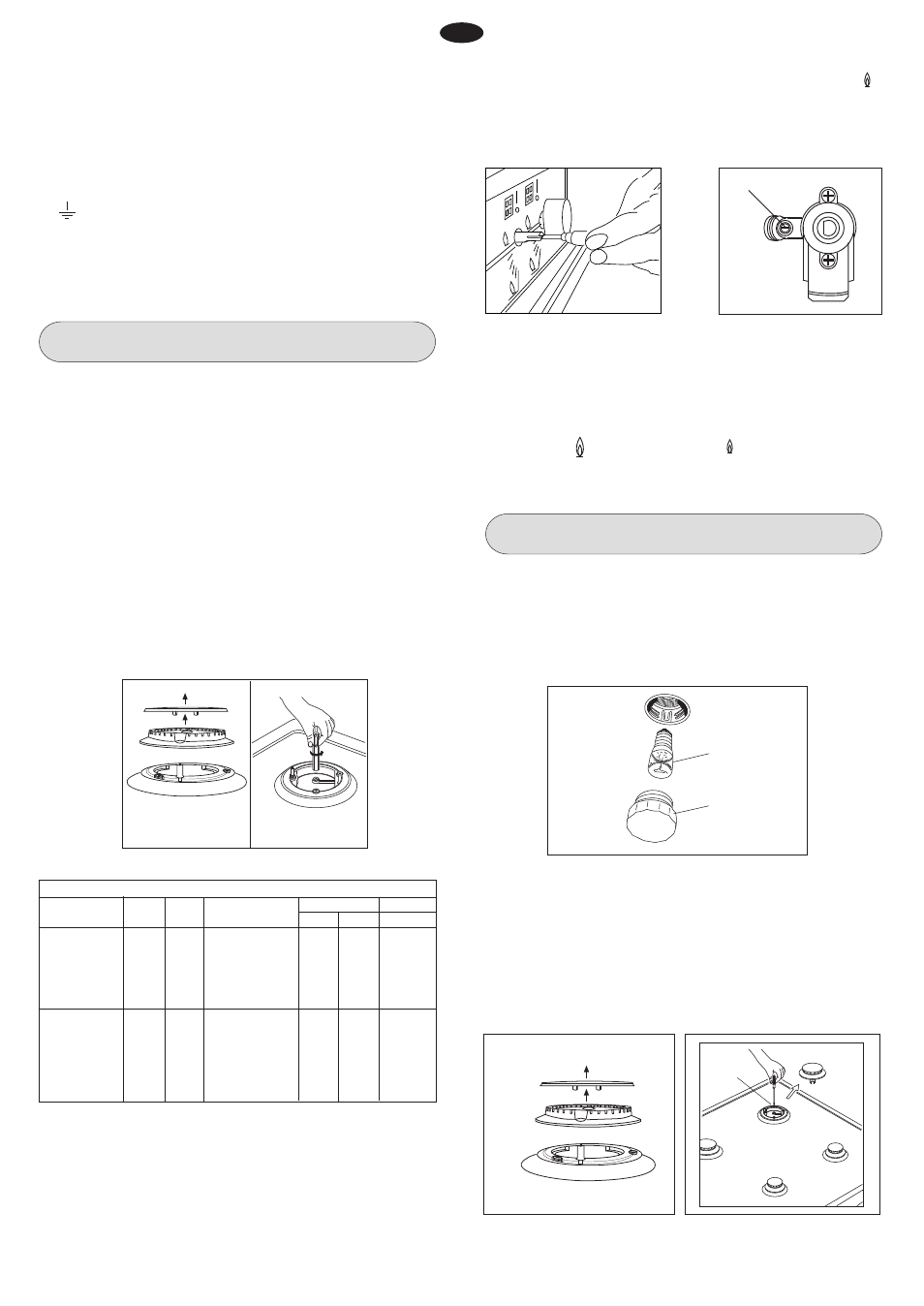

Fig. 14

Fig. 15

MINIMUM FLOW ADJUSTMENT FOR WORK-TOP TAPS

In order to adjust the minimum, act as follows: switch the burner

on, and turn the knob towards the minimum flow position .

Remove the knob from the tap, introduce a little screwdriver in

the tap rod (fig. 14).

Attention: in taps with security valve, the minimum adjusting screw

“Z” is placed outside the rod tap (fig. 15).

Unscrew the adjusting screw in order to increase the flow or screw

it to decrease the flow.

The right adjustment is obtained when the flame has a length of

about 3 or 4 mm.

For butane/propane gas, the adjusting screw must be tight

screwed.

Make sure that the flame does not go out passing quickly from

the max. flow to the minimum flow .

Assemble the knob again.

WARNINGS

Isolate the cooker from the electricity supply before attempting to

replace the oven lamp.

The oven lamp used is of a special type withstanding high

temperatures. To replace it, act as follows: disassemble the

protecting glass (A) and replace the burnt lamp with one of the

same type. Reassemble the protecting glass.

Fig. 16

Fig. 13

A

B

DISASSEMBLE OF WORK-TOP

In case it is necessary to repair or replace the inside components,

act as follows:

Remove the grids, remove burners and flame-spreaders (see

fig. 17), unscrew the visible screws “V” placed on the work-top

(see fig. 18). Disassemble the work-top by unscrewing the 4 rear

screws “A” (see fig. 19). In this way it is possible to lift the work-

top and to reach the inside components.

Fig. 18

Fig. 17

V

10

GB