MEDC XB15 Manuel d'utilisation

Page 6

5.0 MAINTENANCE

During the working life of the unit, it should require little or no maintenance. GRP will resist attack by most acids,

alkalis and chemicals and is as resistant to concentrated acids and alkalis as most metal products.

However, if abnormal or unusual environmental conditions occur due to plant damage or accident etc., then visual

inspection is recommended.

If the unit requires cleaning, then only clean exterior with a damp cloth to avoid electro-static charge build up.

Replacement of the xenon tube (see below) can be carried out by competent site personnel. Other repairs should be

undertaken by returning the unit to MEDC.

If a unit fault should occur, then the unit can be repaired by MEDC. All parts of the unit are replaceable.

If you acquired a significant quantity of units, then it is recommended that spares are also made available. Please

discuss your requirements with the Technical Sales Engineers at MEDC.

Removing / replacing xenon tube

Unscrew the set screw (2.0mm A/F hexagon key) in the flange of the cover 3 full turns (Do not fully unscrew).

Unscrew and remove the cover and lens assembly using the spanner supplied to gain access to the inside of the

unit.

Remove the old tube by unscrewing the terminal block fixings. The replacement tube can now be fitted (see xenon

tube installation sheet, which is supplied with the replacement tubes)

Once the new tube has been correctly fitted, replace the cover assembly, ensuring the cover is fully screwed down.

There should be a maximum gap of 0.0075” (0.2mm) between the faces of the cover and enclosure to ensure o-

ring compression. Ensure the cover seal is correctly seated in its groove during re-assembly. Re-tighten the grub

screw (2.0mm A/F hexagon key) in the cover flange to secure the cover.

6.0 SPECIAL CONDITIONS FOR SAFE USE

1. Painting and other surface finishes, other than those applied by the manufacturer, are not permitted

2. In order to maintain the dust tight integrity of the enclosures (IP6X), the threads of cable entry devices and

stopping plugs shall be sealed in accordance with the applicable code of practice for flameproof

installation.

7.0 CERTIFICATION/APPROVALS

Please refer to the marking on the unit for specific approval details

UL listed for use in

Class I, Div. 2, Groups A, B, C & D

USA (USL)

Class II, Div. 2, Groups F & G

Class I, Zone 1, AEx d IIB & IIC

and Canada (CNL)

Class I, Div. 2, Groups C & D

Class II, Div. 2, Groups F & G

Class I, Zone 1, Ex d IIB

UL Standards

UL60079-0, UL60079-1, UL50

UL1638 – Ordinary Locations

UL1638 UXUB Marine Listed

CSA-C22.2 No. 205, CSA E60079-0, CSA E60079-1

ULC Standards

CAN/ULC-S526-07

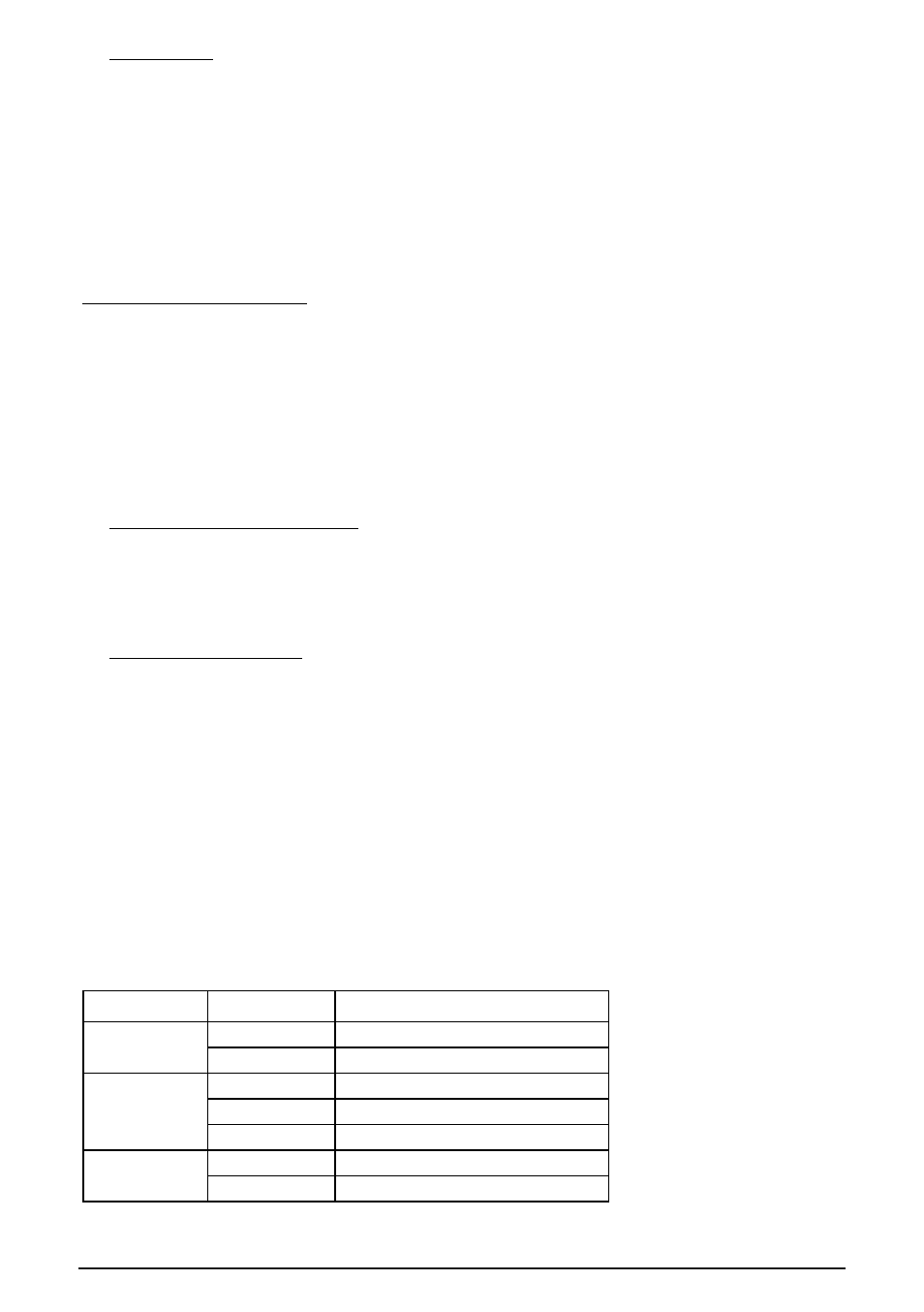

Tube Energy

T-Rating

T

amb

15J

T4

-67°F to +158°F (-55°C to +70°C)

T5

-67°F to +104°F (-55°C to +40°C)

10J

T4

-67°F to +158°F (-55°C to +70°C)

T5

-67°F to +131°F (-55°C to +55°C)

T6

-67°F to +104°F (-55°C to +40°C)

5J

T5

-67°F to +158°F (-55°C to +70°C)

T6

-67°F to +131°F (-55°C to +55°C)

01/15

© MEDC 2015