10095-lp rev b (english) pg04, Opd equipped cylinder hose & regulator, Disconnection – Broil King Porta Chef Porta-Chef™ 320 Portable Gas Grill Owner's Manual Manuel d'utilisation

Page 4

OPD EQUIPPED CYLINDER HOSE & REGULATOR

4

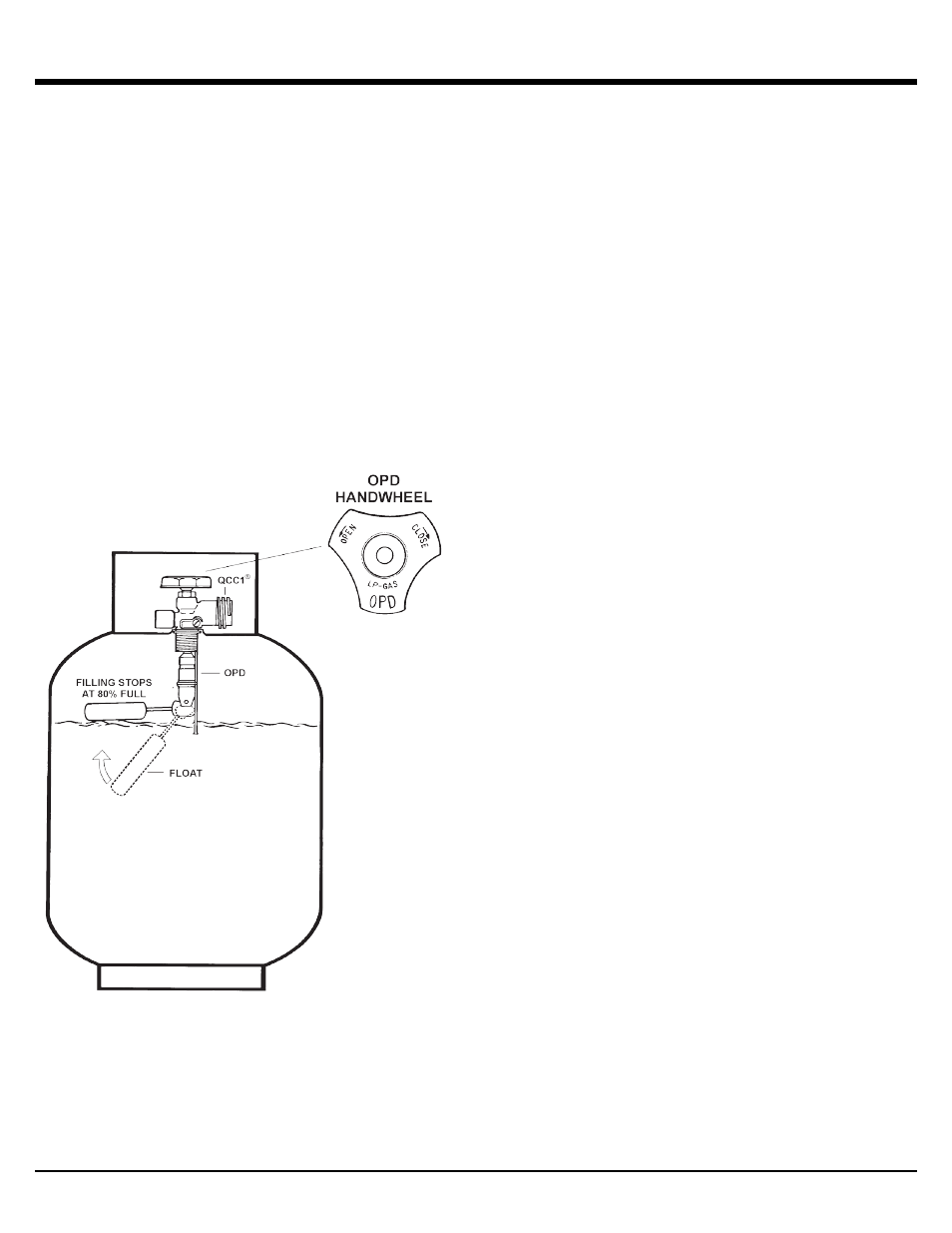

OVERFILL PREVENTION DEVICE

1. The standard for outdoor gas appliances, ANSI Z21.58/

CAN/CGA-1.6, requires that appliances be used with

cylinders equipped with an Overfill Prevention Device

(OPD).

2. The OPD is designed to reduce the potential for the

overfilling of propane cylinders, thus reducing the

possibility of relief valve discharges of raw propane.

The

OPD causes a slower purge/fill operation

. Some

consumers have been advised by filling stations that these

cylinders are “defective.”

This is not a defect

. Some

propane filling stations may not be aware of this device and

its effect on the purge/fill operation.

3. New OPDs coming onto the market have technology that

allows for much greater BTU outputs which will decrease

the amount of time it takes to purge a cylinder.

IDENTIFICATION

To identify these cylinders, the OPD handwheel has been

standardized to the shape shown.

1. All models are equipped with a hose and regulator with a

QCC®-1 Quick Closing Coupling.

2. The QCC® coupling contains a magnetic Flow Limiting

Device which will limit the flow of gas should there be a

leak between the regulator and the appliance valve. This

device will activate if the cylinder valve is opened while

the appliance valves are open.

Be sure the appliance

valves are off before the cylinder valve is opened to

prevent accidental activation

.

3. The QCC® coupling incorporates a heat sensitive hand

wheel that will cause the back check module in the QCC®

cylinder valve to close when exposed to temperatures

between 240° and 300°F. Should this occur, do not

attempt to reconnect the hand wheel. Remove

hose/regulator assembly and replace with a new one.

4. The pressure regulator is set at 11 inches WC (water

column) and is for use with LP gas only. The hose and

hose couplings comply with CGA Standard CAN 1.83. No

modifications or substitutions should be attempted.

5. Protect the hose from dripping grease and

do not allow

the hose to touch any hot surface

, including the base

casting of the barbecue.

6. Inspect the seal in the QCC® cylinder valve when

replacing the LP gas cylinder or once per year whichever

is more frequent. Replace the seal if there is any

indication of cracks, creases, or abrasion.

7. Inspect the hose before each use. If the hose is cracked,

cut, abraded or damaged in any way, the appliance must

not be operated.

8. For repair or replacement of the hose/regulator assembly,

contact customer service.

CONNECTION

1. Be sure cylinder valve and appliance valves are “OFF.”

2. Place full LP gas cylinder in LP tank well and secure base

as per assembly instructions.

3. Center the nipple in the cylinder valve and hold in place.

Using other hand, turn the hand wheel clockwise until

there is a positive stop.

Do not use tools. Hand tighten

only. When making the connection, hold the regulator

in a parallel with the cylinder valve, so as not to cross

thread the connection

.

4. Leak test connections. See “Leak Testing.” (page 5)

5. Refer to lighting instructions.

To avoid activating the

Flow Limiting Device when lighting, open cylinder

valve slowly with the appliance valves off

. If the Flow

Limiting Device is accidentally activated, turn off cylinder

valve and appliance valves, wait 10 seconds to allow the

device to reset, open cylinder valve slowly, then open the

appliance valve.

DISCONNECTION

Always close LP cylinder valve and remove coupling nut before

moving cylinder from specified operation position.