Ps__sf flyware - en, Eyebolt installation – Yorkville Sound PS15S 15" Parasource Powered Subwoofer (1000W) Manuel d'utilisation

Page 10

weight of cabinet only

PS12SF

4 Top

3/8-16

weight of cabinet only

PS15SF

4 Top

3/8-16

PS18SF

4 Side

weight of cabinet only

3/8-16

DOC-flyware-PS__S-00-1v1. • July 22/2020

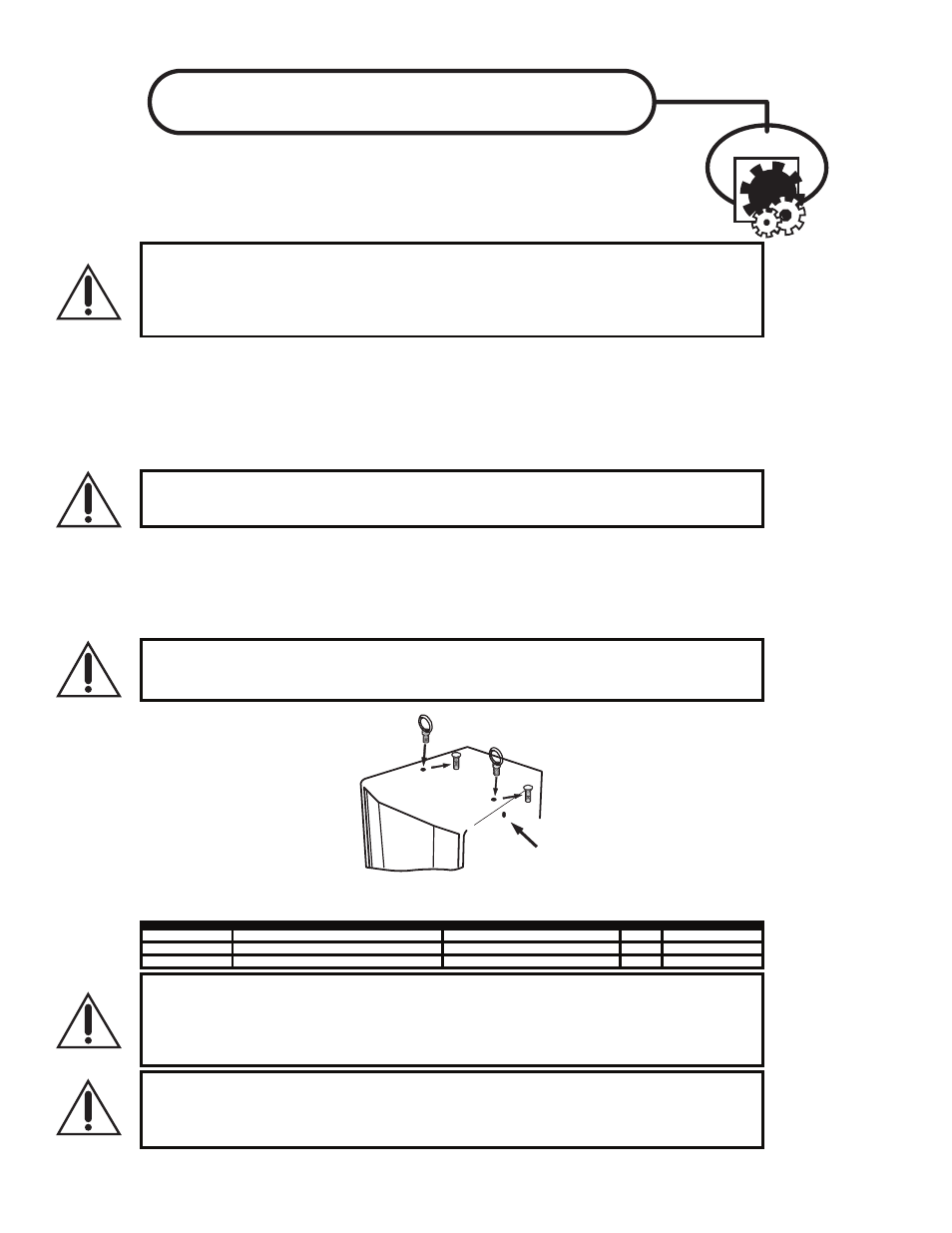

EYEBOLT INSTALLATION

Remove

Flat-Head Bolt

and

replace with

Forged Shoulder Eyebolt!

DO NOT

Remove

Flat-Head Bolts

on the Side of Cabinet/s.

1. DESCRIPTION

Many of the popular models in the Yorkville speaker cabinet line are now equipped with flying

hardware for overhead suspension applications. Depending on the model, two or more internal

braces have been provided for rigging purposes. Each brace contains two bolt holes and provides

center-of-gravity fly-points for use with in-line or angular loads. Many of the models will support

additional suspended cabinets according to their specified working load limits.

IMPORTANT!!

THE RIGGING OF LOUDSPEAKER SYSTEMS IS AN EXTREMELY SERIOUS MATTER. OVERHEAD RIGGING REQUIRES EXTENSIVE

EXPERIENCE, INCLUDING (BUT NOT LIMITED TO) CALCULATING WORKING LOAD LIMITS, HARDWARE INSTALLATION, AND

PERIODIC SAFETY INSPECTION OF ALL HARDWARE AND CABINETRY. IF YOU LACK THESE QUALIFICATIONS, DO NOT ATTEMPT

THE INSTALLATION YOURSELF, BUT INSTEAD USE A PROFESSIONAL STRUCTURAL RIGGER. IMPROPER INSTALLATION CAN

RESULT IN BODILY INJURY OR DEATH. CONSULT A STRUCTURAL ENGINEER TO CALCULATE ADDED LOADS FOR A BUILDING.

STRUCTURAL REINFORCEMENT MAY BE NECESSARY TO INSURE A SAFE INSTALLATION.

2. REQUIRED TOOLS

4.5mm (7/32”) Hex Wrench

Thread lock adhesive (Removable Type)

3. EYEBOLT INSTALLATION

a) Using a 4.5mm (7/32”) hex wrench, remove the flat head bolts from the top or bottom of the speaker enclosure

to expose the tapped holes (on TX models, the flat head bolts are located within the track rails), as shown below.

Be sure to keep these handy as they will be needed to seal the cabinet after the eyebolts are removed.

IMPORTANT!!

USE ONLY LOAD RATED FORGED EYEBOLTS. THESE MAY BE PURCHASED THROUGH YORKVILLE SOUND OR ATM FLY-WARE™.

TO INSURE CABINET-BRACING STRENGTH, MAKE SURE ALL FLY-POINTS ARE SECURED WITH EITHER AN EYEBOLT OR FLAT

HEAD HEX BOLT.

b) Place a drop of thread-lock adhesive on the threads of the eyebolt and insert one into exposed hole. Tighten each

eyebolt by hand until its fits snugly against the cabinet. Further tighten each eyebolt by rotating it another half turn. Be

sure to insert eyebolts in the threaded hole directly in-line with the suspension cable. Always follow the eyebolt

manufacturers installation and use instructions.

c) Suspend each cabinet according to working load calculations and practices recommended by the rigging

hardware manufacturer.

IMPORTANT!!

ON MODELS WITH ONLY TWO TOP SUSPENSION POINTS THE SUPPLIED PULL BACK AT THE REAR OF THE BOTTOM

CENTER PANEL OF THE CABINET IS NOT TO BE USED AS A SUSPENSION POINT. THIS POINT TO BE USED FOR PULL BACK

PURPOSES ONLY.

IMPORTANT!!

READ ALL ENCLOSED INSTRUCTIONS ABOUT PROPER USE OF HARDWARE. TO INSURE PROPER

INSTALLATION, FOR TECHNICAL INFORMATION ON SUSPENSION TECHNIQUES AND EXTERIOR ACCESSORY INFORMATION

WE SUGGEST CALLING ATM FLY-WARES TECHNICAL SERVICES IN THE UNITED STATES AT (310)639-8282 MONDAY THROUGH

FRIDAY FROM 9 AM TO 6 PM (PST) OR FAX AT (310)639-8284. YORKVILLE SOUND MAKES NO CLAIMS AS TO THE SAFETY OF

THE ENCLOSURES IF RECOMMENDED LOAD LIMITS AND HARDWARE ARE NOT STRICTLY ADHERED TO. NOR DOES IT MAKE

ANY SAFETY CLAIMS TO THE RESULTANT INSTALLATION.

IMPORTANT!!

TRACK RAILINGS: UNITS THAT INCORPORATE THE TRACK RAILING SYSTEM HAVE THE SAME WORKING LOAD

LIMITS AS THEY DO WHEN THEY ARE USED WITH EYEBOLTS. THESE RATINGS MAY BE LIMITED AND BASED ON THE RATINGS

OF THE TRACK FITTINGS THEMSELVES. PLEASE ENSURE THAT THE RATING OF THE CERTIFIED TRACK FITTINGS EXCEEDS

NECESSARY WORKING LOAD LIMITS

.

4. WORKING LOAD LIMITS

Specified working load limits have been determined for the enclosure as follows: