MEDC LD15 Manuel d'utilisation

Page 8

6.0 SPECIAL CONDITIONS FOR SAFE USE

1. Painting and other surface finishes, other than those applied by the manufacturer, are not permitted

2. In order to maintain the dust tight integrity of the enclosures (IP6X), the threads of cable entry devices and stopping

plugs shall be sealed in accordance with the applicable code of practice for flameproof installation.

7.0 CERTIFICATION/APPROVALS

Please refer to the marking on the unit for specific approval details

UL listed for use in

Class I, Div. 2, Groups A, B, C & D

USA (USL)

Class II, Div. 2, Groups F & G

Class I, Zone 1, AEx d IIB & IIC

and Canada (CNL)

Class I, Div. 2, Groups C & D

Class II, Div. 2, Groups F & G

Class I, Zone 1, Ex d IIB

UL Standards

UL60079-0, UL60079-1, UL50

UL1638 – Ordinary Locations

CSA-C22.2 No. 205, CSA E60079-0, CSAE60079-1

ULC Standards

CAN/ULC-S526-07

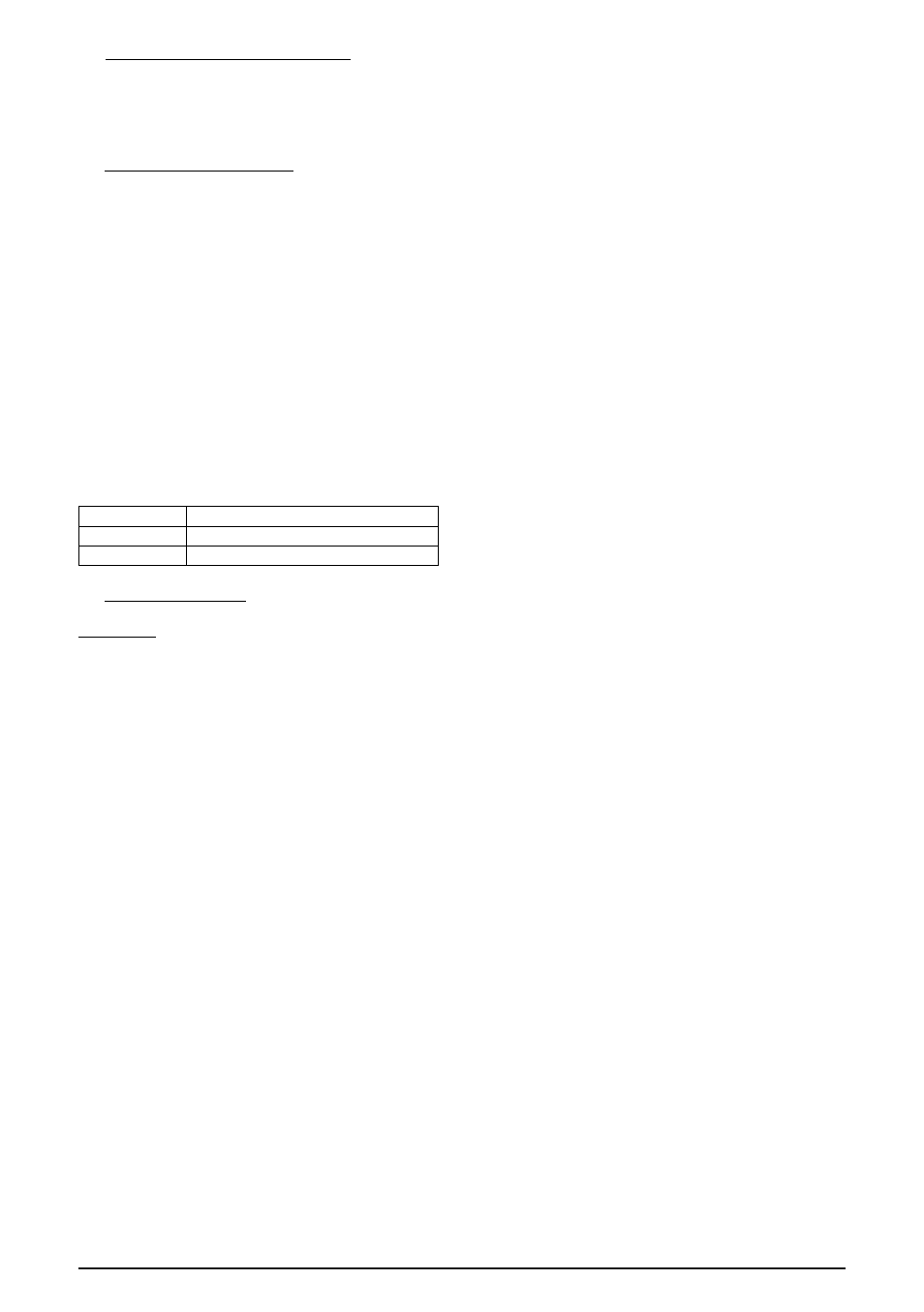

T-rating (T

G

)

T

amb.

T5

-67°F to +158°F (-55°C to +70°C)

T6

-67°F to +131°F (-55°C to +55°C)

8.0 FUNCTIONAL SAFETY

Introduction

The LD15 Beacon has been designed for use in potentially explosive atmospheres and harsh environmental conditions. The

glass reinforced polyester enclosures are suitable for use offshore or onshore, where light weight combined with corrosion

resistance is required.

The safety function of the Beacon is to provide an intermittent or permanent spherical visual warning light when the correct

voltage is applied to the unit. The Beacon is designed to operate on a supply voltage of 24vDC with a tolerance of +/- 20%.

Under No fault (Normal) Operating conditions the LD15 Beacon will provide a spherical visual warning light when required

by the system, with no time delay or other faults.

Under fault conditions the failure mode of the Beacon is a failure to provide a spherical visual warning light. For the failure

rate associated with this failure mode please refer to the table below.

01/15

© MEDC 2015